Extraction Parachute Jettison System

The extraction parachute jettison system (EPJS) allows jettisoning of an extraction parachute, extraction line, and line panel in the event of a malfunction during the extraction phase of the airdrop. The system is capable of jettisoning a single 15, 22, or 28-foot extraction parachute.

In our FXC facility, the Extraction Parachute Jettison System (EPJS) was designed and produced for the ARMY and is a significant component of the Advanced Low-Velocity Air Drop System described in the Capability Production Document (CPD) of September 2006. These units are approved equipment in US Air Force air mobility aircraft and are a designated system for the Airbus A400M and Embraer KC-390 military cargo aircraft. The EPJS is currently used by the military services of Japan, Israel, the United Kingdom, Australia, and Belgium.

The FXC EPJD – Light & Heavy was designed and qualified for loads from 27,000-42,000 pounds and is currently in the DoD inventory. Also, FXC designed and proof-tested a super-heavy EPJD version (60,000 pounds).

In normal cargo aerial delivery operations, the extraction parachute is deployed and the cargo pallet exits the aircraft.

A malfunction of this process of extracting palletized cargo during an in-flight delivery puts the the aircraft and the safety of the entire crew at risk.

The capability of remotely jettisoning the high drag-producing extraction parachutes in the event of a cargo pallet exit malfunction is essential. Currently, if a malfunction occurs the loadmaster must position themselves at the ramp exit and between the cargo pallet and extraction parachute main lines. Once at that position the loadmaster must manually cut-away the extraction parachute main lines by hand. This is very dangerous because the cargo pallet load could break away and strike the loadmaster while the main extraction lines are being cut.

The FXC Extraction Parachute System (EPJS) concept has been developed to jettison malfunctioning parachutes remotely, quickly and safely.

The system requires no modification to the aircraft and only requires a 28 VAC power source. One EPJS is required for each cargo pallet.

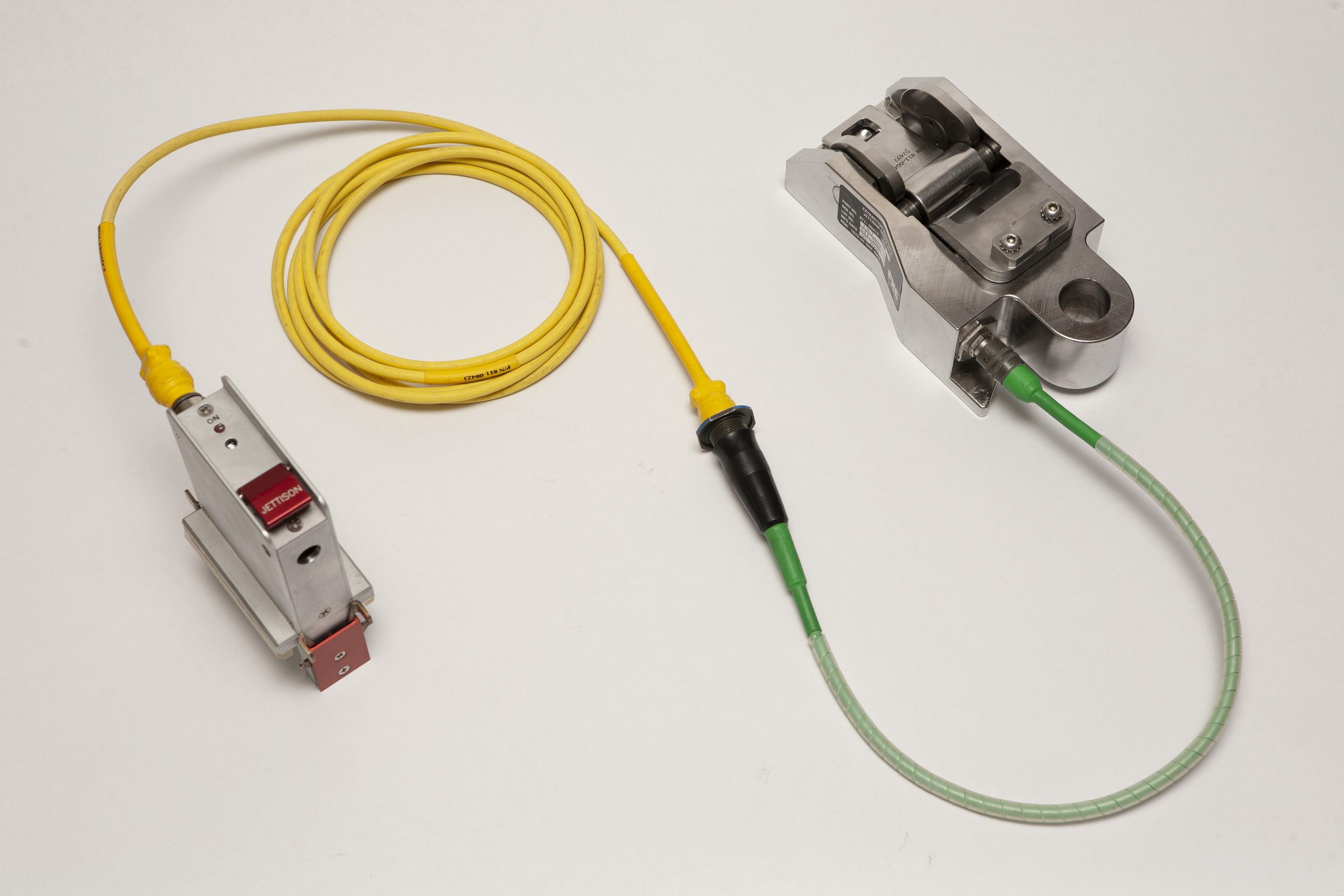

The EPJS is comprised (refer to diagram) of the following major assemblies:

- Extraction Parachute Jettison Device (EPJD) - Couples the extraction line with the 3-point link assembly. The EPJD contains a pyrotechnic squib that, when activated remotely by the Loadmaster, releases the main lines connected to the extraction parachutes

- Y-Connector Mounting Box - Is an electrical circuit and connection assembly that is the junction between the Loadmasters Control Box and the firing of the squib in the EPJD. It is secured to the floor rings of the aircraft and is adjustable with an extendable mounting tube. An LED signals power continuity and readiness to activate the EPJD squib in the LAMP TEST Mode. There is one Y-Connector Mounting Box for each cargo pallet. Operating the JETTISON Switch on the Control Box actuates the squib firing circuit in the EPJD via the Y-Connector Mounting Box.

- Control Box - Contains the Power switch, circuit breaker, LAMP TEST and guarded JETTISON switches. A dimmer adjust knob controls the brightness of the LED’s on the Y-Connector Mounting Box.

- Squib & Cable - Is an electrically initiated gas generator mounted into the EPJD that when activated severs the main extraction line webbing.

- Cables - Interconnecting electrical cables between the Y-Connector Boxes, the EPJD, and Control Box are provided. There is a Power cable that connects to the Control Box from the 28VAC aircraft power outlet.

Additional information

| NSN | 1670-01-544-7425 |

|---|